Switches Aligned, Route Clear! 🚦

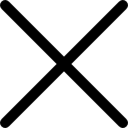

What keeps a train moving safely along the rails? We often think of the driver in the cab, the control room watching over operations, or the train’s own sophisticated onboard systems. But none of these could function without something more humble, more discreet, and yet absolutely essential: the signaling equipment on the ground. It is this invisible infrastructure — the trackside elements — that truly makes the railway safe.

In the beginning, signaling was simple. Too simple. A flag waved by a worker at the station, a lamp held out in the night, a semaphore arm against the sky. These were the first languages of railway safety. They spoke directly to the driver’s eyes and judgment, nothing more. But as trains grew longer, faster, and heavier, vision alone was no longer enough. Human reaction times could not keep pace with steam power, and a system that had been born out of practicality began to show its fragility. Collisions, derailments, and misunderstandings were frequent. Out of necessity, railways invented signaling as we know it today: a combination of physical devices on the ground and logic systems that transform the movement of trains into something predictable, controlled, and above all safe.

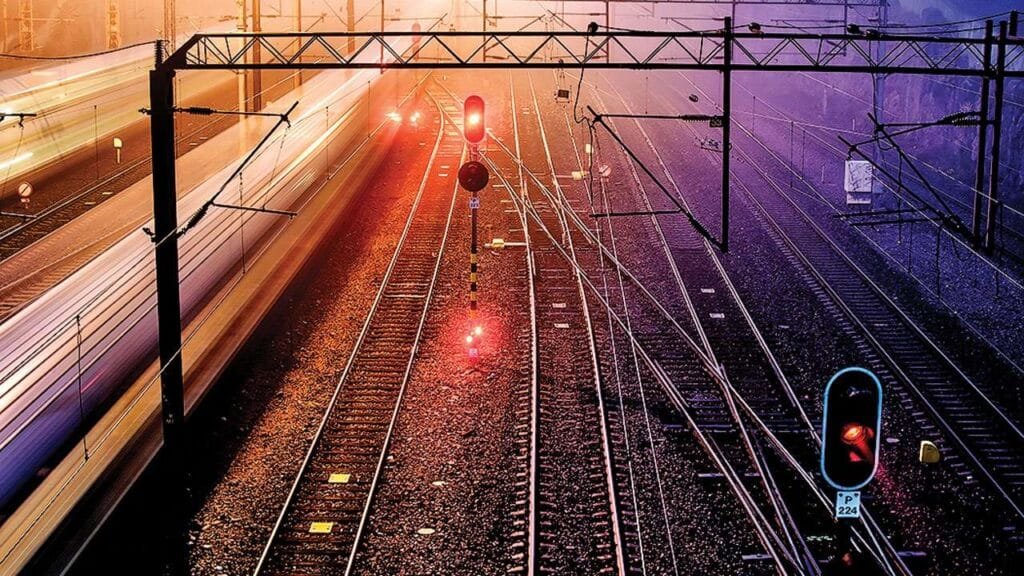

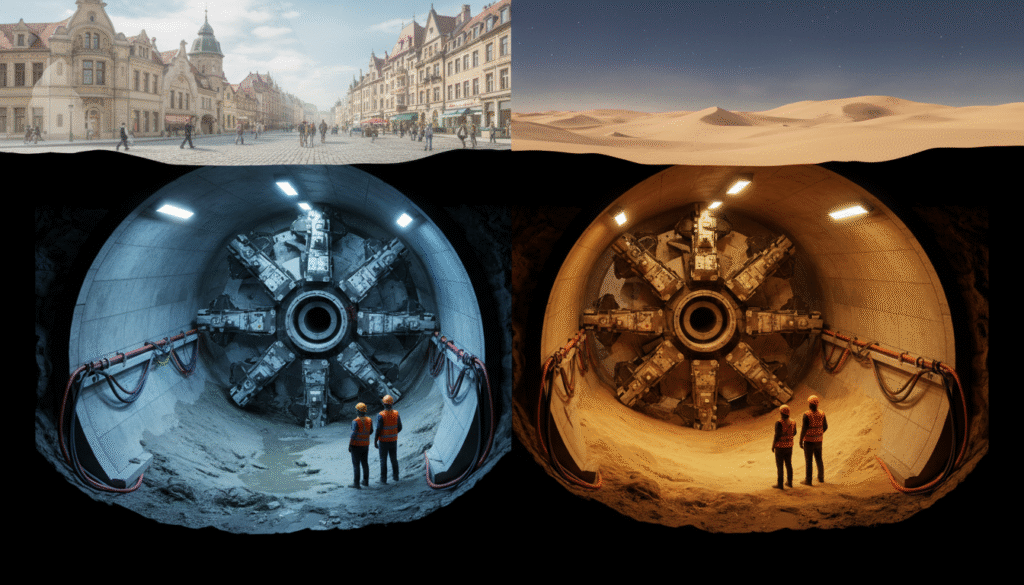

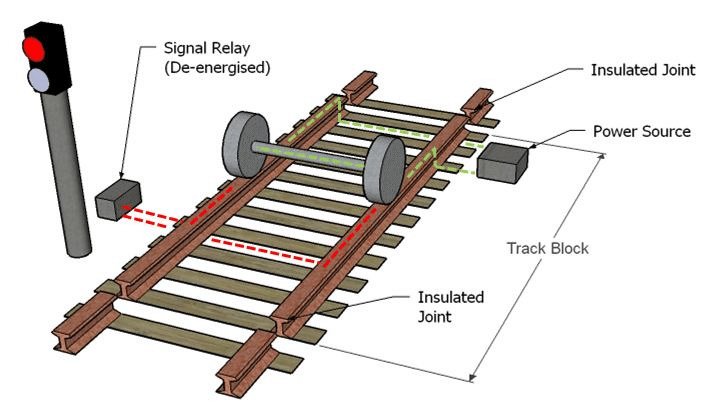

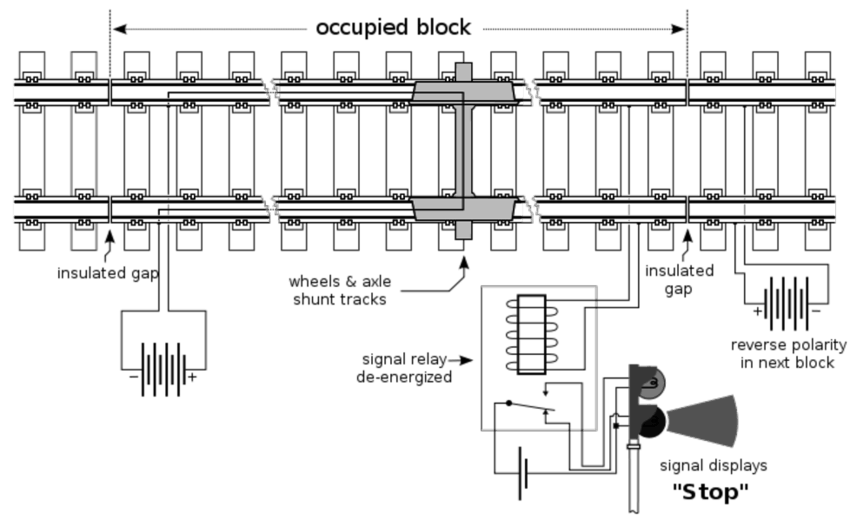

At the heart of signaling is a deceptively simple question: is the track ahead free, or not? Answering that question required an invention that may not look impressive but revolutionized safety: the track circuit. Imagine the rails themselves forming an electrical circuit. When no train is present, the current flows uninterrupted. When a train’s wheels and axles pass over, they short the circuit, proving that the section is occupied. It is elegant, automatic, and reliable. Where track circuits cannot be used — for example, in areas where rust, sand, or climatic conditions disturb conductivity — railways use axle counters, which detect and count every wheel entering and leaving a section. The principle is the same: absolute certainty about occupancy. Because without knowing whether the rails are clear, no system of signals or instructions can ever be safe.

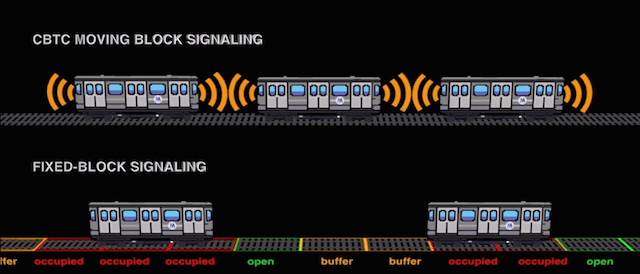

This certainty is the foundation of one of the most essential principles in railway operations: the block system. The line is divided into consecutive blocks, and only one train may occupy a block at a time. As long as the track circuit or axle counter proves that a block is clear, another train can be admitted; if not, the protecting signal must remain at danger. Whether applied as a fixed block — discrete sections of track protected by signals — or as a moving block, as used in advanced systems like ETCS Level 3 and CBTC, the principle is identical: trains can only follow one another when separation is guaranteed by the infrastructure. Detection without the block concept would not be sufficient to prevent collisions.

Yet detection is only the first step. Trains must also receive information: speed limits, upcoming restrictions, and the authority to proceed. For that, signaling began to place intelligence directly into the track. Small electronic devices called balises, often unnoticed between the sleepers, now transmit data directly to trains. In ETCS, the European Train Control System, these balises are essential. Balises provide the train with fixed reference points and additional information, which the onboard ETCS system uses to calculate speed profiles and braking curves. In metro systems running CBTC — Communications-Based Train Control — similar ground elements communicate continuously with onboard systems, allowing trains to run with minimal headway and, in some cases, without drivers at all. It may look like the future, but it is still grounded in physical devices fixed to the track.

And then there is the most dramatic of ground elements: the point machine. At first glance, a turnout — a simple switch where one track becomes two — seems straightforward. But its safe operation is anything but. The rails must move precisely into position, lock firmly, and report back their status. Point machines, usually housed in robust metal casings by the track, do exactly this. They are the muscles of the signaling system, shifting tons of steel with millimetric precision. And because a single error — a switch left half-open — could lead to derailment, they are built to be redundant, monitored, and fail-safe.

Of course, many people still imagine signaling as lights beside the track. And indeed, light signals remain a powerful symbol of railways. A red light to stop, a green light to go, a yellow to warn: simple, universal, effective. Even as cab signaling becomes the standard on high-speed lines, traditional signals endure across vast parts of the world’s networks. Light signals remain widely used on conventional lines, while in ETCS Level 2 and CBTC networks they can be reduced or even eliminated, with Movement Authority shown directly in the cab (the Movement Authority will be the subject of a separate dedicated article.)

Overseeing everything is the interlocking — the brain of the system. Once, interlockings were mechanical machines with rows of heavy levers connected by steel rods and wires. Later came relay interlockings, massive halls filled with thousands of clicking relays. Today, most are computerized, with software logic replacing physical mechanisms. But the principle remains unchanged: safety by exclusion. If one route is set and locked for a train, no other route that conflicts with it can be allowed. It is a logical fortress, and its decisions flow outwards to the point machines, the signals, the balises, and every element along the track.

And what ties all this together? The modest line-side cabinets, cables, and junction boxes scattered along the right of way. Inside are relays, circuit boards, power supplies, and communication modules. They look unremarkable — grey boxes with warning stickers — yet they are the nervous system of the railway. They carry the commands, check the confirmations, and make sure every piece of the puzzle is connected. Without them, the interlocking would think in isolation, and the signals would shine blindly into the night.

When you step back, what emerges is fascinating. Even the most advanced train — equipped with satellites, onboard computers, and algorithms — is still dependent on these humble ground devices. They are the anchors of certainty in a system that must never tolerate doubt. A driver can only accelerate confidently if the track circuit has proved the way clear. A control center can only authorize a route if the point machines have locked in position. A train can only rely on its cab display if the balises have transmitted accurate data. The visible glamour of modern railway technology rests upon the invisible discipline of its trackside elements.

There is also a kind of poetry here. Railways are about movement, yet safety comes from things that do not move: relays in a cabinet, magnets between sleepers, rails carrying current, machines bolted into the ballast. The ground itself is what speaks to the train, quietly, constantly, with absolute clarity. And this conversation — between train and earth, between steel and circuit — is what makes every journey possible.

In the coming articles, we will take a closer look at each of these elements. We will explore how track circuits actually work, why axle counters are sometimes preferred, how interlockings evolved from lever frames to software, how the block system is being redefined with moving block technology, and how point machines are tested to ensure they never fail when it matters most. Because only by understanding the ground can we truly understand how railways move.

References and Further Reading

- UIC – Code on Signalling Principles, Track Circuits, and Block Systems

- ERA (European Union Agency for Railways) – Technical Specifications for Interoperability (TSI) – Control-Command and Signalling

- (CCS)CENELEC – EN 50126 / EN 50128 / EN 50129: Railway Applications – Reliability, Availability, Maintainability and Safety

- ResearchGate – “Basic track circuits (a) unoccupied and (b) occupied”, figure illustrating block sections and insulated joints

- ResearchGate – “Schematic drawing of track occupied circuit (Rys. 3)”, diagram showing AC/DC circuit variations

- Railwaysignalling.eu – “Introduction to CBTC system description”, overview of moving block principles and CBTC features

- MetroRailNews – “Opportunities in Railway Signalling & Telecommunications”, article on current developments and industry perspectives