Switches Aligned, Route Clear! 🚦

When tunneling beneath a city, engineers must often go beyond brute force. In the case of Milan’s Metro Line 4, cutting-edge methods like Artificial Ground Freezing (AGF) using liquid nitrogen have allowed excavation in areas where traditional techniques would falter.

But what exactly is AGF? Why freeze the earth? And how does this silent, invisible force enable metros to glide beneath our feet?

A Race Against Water and Time

It’s 6 a.m. in central Milan. Beneath the cobbled elegance of Piazza San Babila, the ground is alive with tension. Not from traffic or tourists, but from pressure meters, thermocouples, and pipes silently transforming the wet, unstable soil into something solid and safe. Engineers in the control cabin sip their coffee while watching temperature curves flatten on their screens. Outside, massive silos hiss softly as they feed liquid nitrogen into a dense forest of cannulas beneath the city.

This is Artificial Ground Freezing in action: an invisible guardian that makes it possible to tunnel under fragile historic buildings, without triggering cracks or subsidence above.

Why Freeze the Soil?

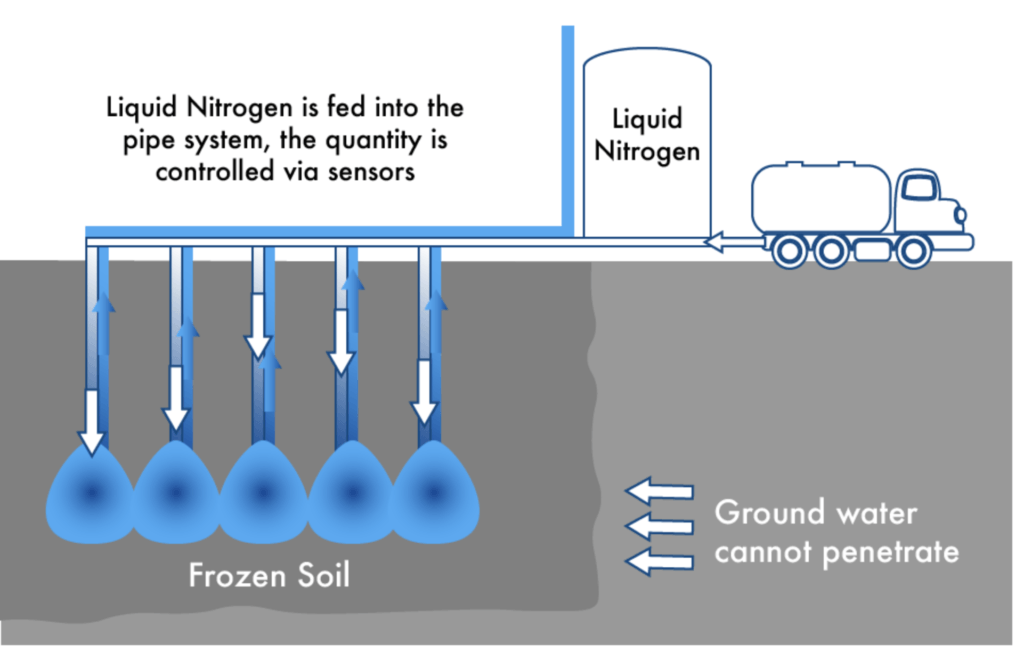

Subway lines often traverse complex geological strata, from waterlogged silts to soft clays with high permeability. In central Milan, where Line 4 had to dive under centuries-old structures, groundwater and unstable soils posed major risks for settlement and collapse.

AGF temporarily transforms saturated, unstable ground into a solid, ice-like mass. This allows Tunnel Boring Machines (TBMs) or mined excavation to proceed safely through otherwise impassable zones.

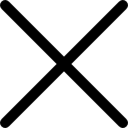

How Does Artificial Ground Freezing Work?

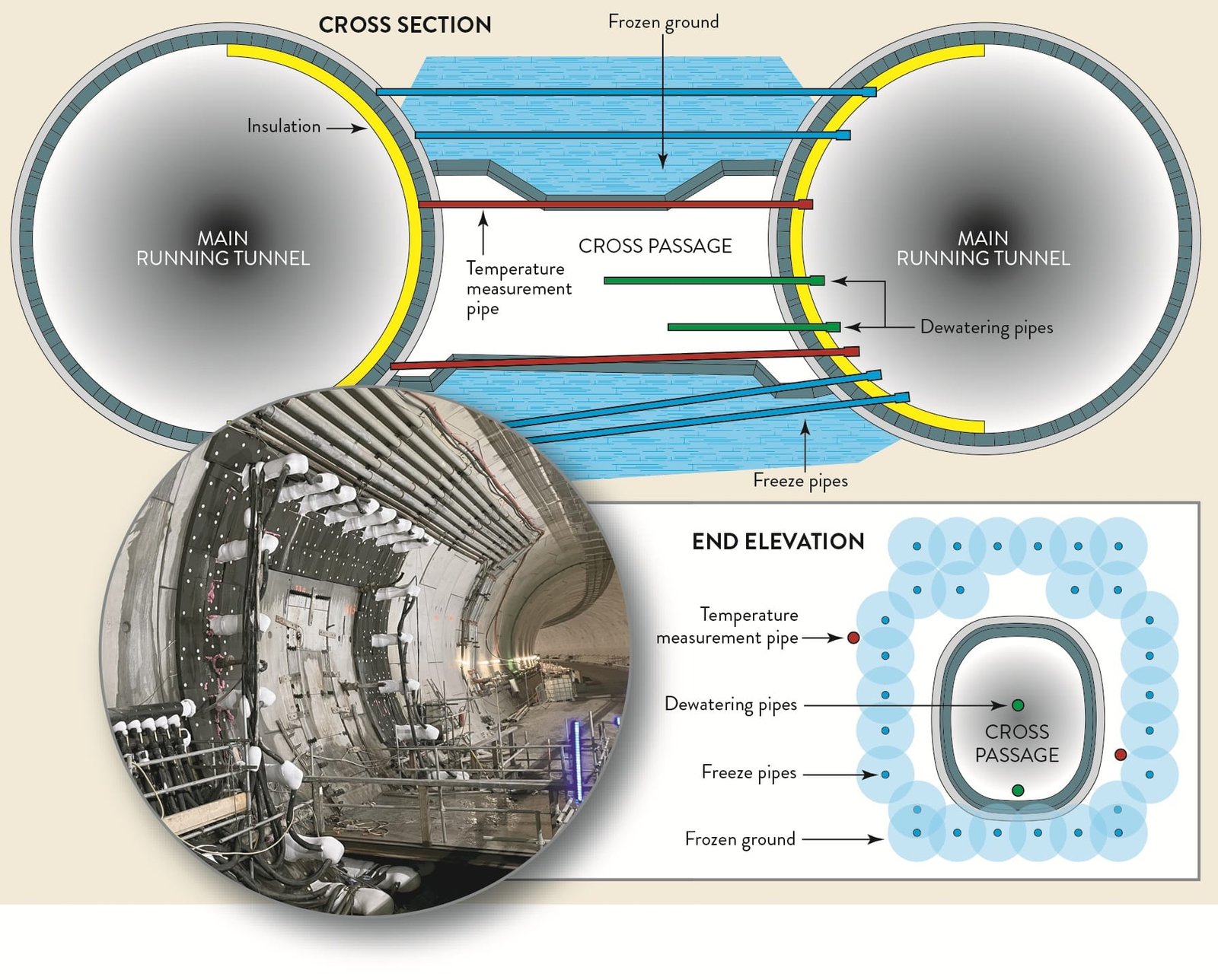

The process involves a precise choreography of equipment, timing, and control.

- Design Phase: Engineers begin with detailed geotechnical investigations. Finite element simulations are run to model thermal diffusion and water movement in the soil.

- Freeze Pipe Installation: Steel pipes known as “freeze pipes” or cannulas are drilled vertically or inclined around the future tunnel or shaft perimeter. Their layout must create a continuous frozen barrier.

- Support Infrastructure: Above ground, cryogenic liquid nitrogen silos are installed and connected to a distribution system. Each pipe is fed with liquid nitrogen at -196°C. This system is managed from a dedicated control unit, where operators regulate flow, monitor temperatures, and ensure uniform freezing.

- Formation of the Frozen Wall: Over a period of days to weeks, pore water in the soil freezes, bonding particles together. The goal is a uniform frozen wall, typically verified by a network of thermocouples and automated alarms.

- Excavation Phase: Once the soil reaches the target temperature and stability, excavation can begin. The frozen ground provides both structural support and a watertight barrier—critical when working below the water table.

- Thaw and Demobilization: After construction, nitrogen flow is stopped and the ground is allowed to thaw naturally. Cannulas are removed, and the site is backfilled and restored.

Nitrogen vs. Brine: Why Liquid Nitrogen in Milan?

While many AGF projects use brine chilled via refrigeration plants (e.g. -30 to -40°C), Milan opted for liquid nitrogen in several points of Metro 4. The reasons include:

- Speed: Nitrogen freezes soil much faster than brine.

- Compact setups: No need for large refrigeration plants.

- Space constraints: Crucial in tight urban environments like San Babila and Tricolore.

Metro 4, Milan: A Case Study

In the San Babila and Tricolore station shafts, AGF with liquid nitrogen was used to stabilize sandy and gravelly soils below the water table.

This technique allowed excavation directly beneath historical buildings with minimal ground movement. A dense web of thermocouples monitored soil temperatures in real time. Vibration sensors and inclinometers in adjacent buildings confirmed that differential settlements remained within millimetric tolerances.

The use of AGF was not a choice of convenience, but one of necessity. The ground could not be dewatered without risking collapse. Freezing was the only method capable of creating a temporary yet robust environment for tunneling.

Advantages of Ground Freezing

- Excellent sealing capacity for water-bearing soils

- Creates strong, temporary structural support

- Avoids the need for groundwater pumping, ideal in urban areas

Challenges and Limitations

- High energy and operational costs (especially with liquid nitrogen)

- Limited duration: ground must remain frozen throughout the works

- Requires detailed planning and tight monitoring

What’s Next?

Artificial Ground Freezing is gaining renewed interest thanks to smarter simulations, improved sensor networks, and greater environmental control. Techniques like digital twin modeling are making freeze behavior more predictable and less risky.

In upcoming articles on Beyond Tracks, we’ll explore these future-facing developments: from the digitalization of freeze monitoring to sustainable alternatives to nitrogen. We’ll also break down each component of the AGF process—from the logistics of nitrogen delivery to real-time control room operations—in greater detail.

Conclusion: Engineering the Invisible

Artificial Ground Freezing doesn’t build tunnels—it builds the conditions that make tunnels possible. It turns chaos into control, mud into marble. The silent precision it brings to complex underground work is what allowed Milan’s Metro 4 to move forward beneath one of Italy’s most treasured cityscapes.

Stay with Beyond Tracks as we continue uncovering the invisible forces shaping tomorrow’s railways.

References and Further Reading

- EFNARC Guidelines on Ground Freezing in Tunnelling

- ITA-AITES Report WG6: Use of AGF in Urban Tunnelling

- Herrenknecht AG Technical Reports on Special Excavation Measures

- “Artificial Ground Freezing: State of the Art and Applications” – Journal of Geotechnical and Geoenvironmental Engineering (ASCE)

- Metropolitana Milanese SpA – Metro 4 Project Documentation and Public Reports

- Dapp, S. et al. (2018). “Numerical simulation of AGF for urban shafts.” Tunnelling and Underground Space Technology