Switches Aligned, Route Clear! 🚆

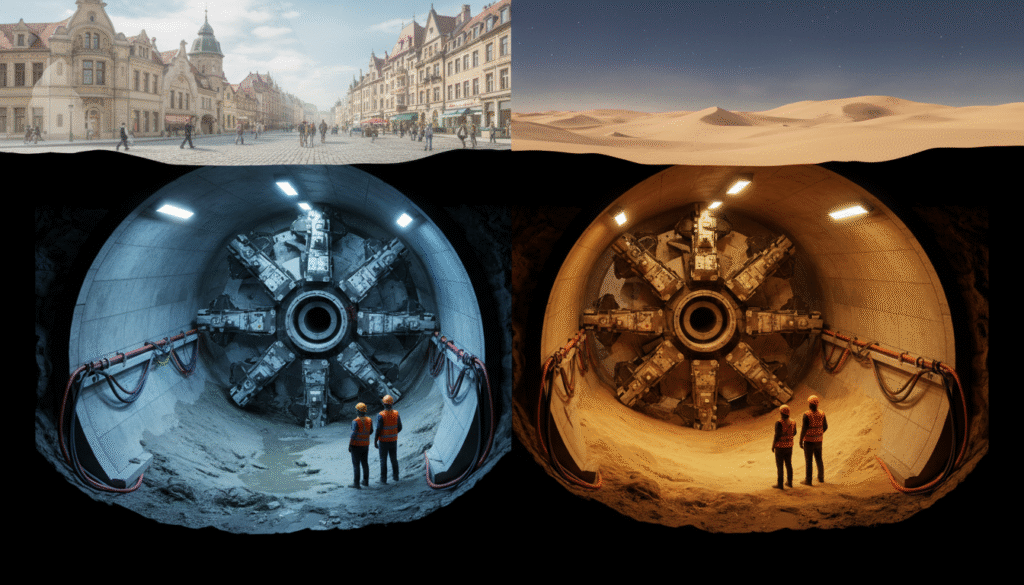

Welcome to the Traction Power System section of Beyond Tracks.

Today, we explore the foundation of modern high-speed railway electrification: the 2×25 kV AC traction power system — a technical solution designed for performance, efficiency, and cross-network compatibility.

If high-speed trains are the visible face of innovation, traction power is the hidden infrastructure that makes those speeds possible. The 2×25 kV system isn’t just a clever voltage configuration — it’s the result of decades of engineering refinement, regulatory standardization, and operational research.

Why AC Electrification?

Rail traction systems are responsible for delivering motive power to trains. Among various electrification choices — DC, single-phase AC, diesel, and hybrid — the railway sector has converged on 25 kV 50 Hz single-phase AC as the most efficient model for new and upgraded high-speed lines.

But when long distances, high speeds, and sustained power draw are involved — like in high-speed rail applications — even conventional 25 kV AC systems face limitations in voltage drop, current return paths, and electromagnetic compatibility.

That’s where the 2×25 kV autotransformer-fed system comes in.

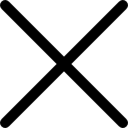

2×25 kV: Understanding the Architecture

The 2×25 kV AC system, originally developed by SNCF and now widely adopted worldwide, enhances a standard 25 kV AC system by delivering 50 kV line-to-line via a split-phase configuration, using autotransformers (ATs) spaced every 10–15 km.

Key Principles:

-

The train still receives 25 kV from the overhead contact line (OCL) relative to the rail.

-

A feeder line runs parallel to the catenary and carries –25 kV with respect to a centrally earthed reference point.

-

Autotransformers connect the catenary, feeder, and rail, creating a balanced 50 kV system with lower line current and reduced voltage drop.

-

The return current is split between the feeder and the rail, minimizing stray currents, reducing rail corrosion, and limiting electromagnetic interference (EMI).

This architecture is compliant with EN 50163 (Supply voltages of traction systems) and EN 50388 (Power supply and rolling stock compatibility), ensuring interoperability and energy efficiency across EU railway corridors.

System Components and Layout

A typical 2×25 kV electrified line includes the following critical infrastructure:

1. Traction Substations

Supplied from the public utility grid (typically 110 or 220 kV three-phase), substations use step-down transformers and single-phase feeders to energize the catenary-feeder pair at 25–0–25 kV. These substations are spaced at 30–50 km intervals based on load and terrain.

2. Autotransformers (ATs)

Installed approximately every 10–15 km, ATs stabilize voltage and equalize load along the line. Rated typically at 15–30 MVA, they ensure reliable operation even during peak traction demand.

3. Feeder and Return System

The feeder wire (carrying –25 kV) runs on the opposite side of the mast from the OCL. The return path consists of the rail and in some systems a dedicated return conductor. This dual-path return ensures minimal voltage drop and compliance with EN 50122-1 on electrical safety and earthing.

4. Sectioning and Paralleling Posts

Used to isolate electrical segments, reroute loads, and allow safe maintenance. Sectioning posts are designed following guidelines like UIC Code 794 and specific national implementation rules.

5. Overhead Contact System (OCS)

The catenary system interfaces with the pantograph of the train, delivering 25 kV to the onboard transformer. The geometry and tension are designed to support speeds of up to 350 km/h, in accordance with EN 50119.

Why 2×25 kV Is the Global HSR Standard

The advantages of 2×25 kV over traditional 25 kV systems are both operational and economic:

-

Lower line current → reduces ohmic losses (I²R losses)

-

Wider substation spacing → reduces capital and maintenance costs

-

Higher fault tolerance and voltage stability

-

Improved EMC → less interference with signalling and track circuits

-

Lower rail return current → minimizes corrosion and complies with EMC Directive 2014/30/EU

These properties make 2×25 kV ideal for high-speed corridors longer than 100 km, especially where traffic density and energy demand are high.

Global Implementations

-

Europe:

-

France (TGV) — pioneered 2×25 kV in the 1980s

-

Spain (AVE) — uses it across nearly all high-speed lines

-

UK (HS1, HS2) — current and future HSR projects designed with 2×25 kV

-

Germany (ICE) — some long-distance corridors use it; however, legacy 15 kV 16.7 Hz remains dominant

-

-

Asia:

-

China — operates the world’s largest high-speed network with 2×25 kV on all new lines

-

India — under the National High-Speed Rail Corporation (NHSRCL), 2×25 kV is being implemented for the Mumbai–Ahmedabad corridor

-

-

USA:

-

California High-Speed Rail — specified 2×25 kV 60 Hz in traction power design documents

-

Northeast Corridor — uses 25 kV 60 Hz on most sections; future upgrades may adopt autotransformer architecture

-

-

Baltic Region (Rail Baltica):

-

Fully aligned with EU interoperability standards, adopting 2×25 kV 50 Hz across the corridor

-

Current Challenges and Research Trends

Even with a proven system, new developments aim to further optimize performance:

-

Dynamic substation control to balance loads across segments in real-time

-

Resonance-free OCS design for higher speed and lower wear

-

Power flow simulation tools to enhance energy efficiency (as recommended in UIC Leaflet 930)

-

Integration with renewable sources and battery-based storage systems to reduce dependency on fossil-fuel grid energy

Advanced studies are also analyzing AC vs. DC performance in mixed-traffic corridors, especially in countries with existing DC legacy systems, evaluating life-cycle costs, transition strategies, and resilience.

Conclusion: The Quiet Giant Behind High-Speed Rail

The 2×25 kV AC traction system may not be visible to passengers — but it is what makes high-speed travel possible. It carries the power to move thousands of tons at hundreds of kilometers per hour, with precision and reliability.

As rail networks expand and demand more energy-efficient, interoperable systems, 2×25 kV will remain at the core of future design — flexible enough for complex grids, strong enough for high demand, and refined enough for international standards.

Here at Beyond Tracks, we’ll continue to explore how energy, engineering, and policy come together to define the railway systems of tomorrow.

Primary Technical References and Verified Sources:

-

EN 50163 – Supply voltages of traction systems

-

EN 50119 / EN 50122-1 / EN 50388 – Catenary, earthing, and electrical compatibility

-

UIC Leaflet 930 – Autotransformer system configuration and return current analysis

-

European Union Agency for Railways (ERA) – CCS/ENE TSI and education materials (2023–2024)

-

California High-Speed Rail Authority – Traction Power Facilities Design Criteria (2023)

-

Rail Baltica Electrification Specification – Public Design Tender Package (2023)

-

UIC Rail System Technical Publications – Electrification studies and system integration reports

-

ResearchGate & IEEE Xplore – Peer-reviewed papers on traction system modeling, power optimization, and EMC mitigation strategies