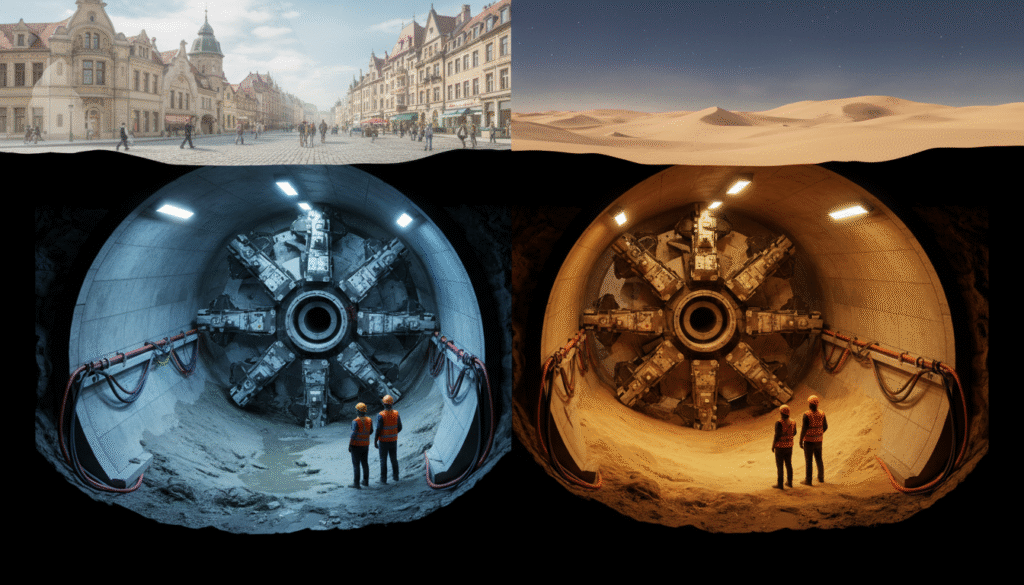

What’s the most important thing for a train to be truly safe? It’s not its speed control, or the signals lining the tracks, or even the strength of its steel frame. It’s something simpler and more fundamental: the absolute certainty that the train can stop — anytime, anywhere, and under any condition.

Because without that, nothing else matters. A system that can’t stop is not just unsafe. It’s unthinkable.

And yet, it wasn’t always this way. In the earliest decades of rail transport, stopping a train was a slow, manual process. Each wagon had its own brake wheel, operated by a brakeman perched atop the car. When the locomotive signaled a stop — often with a flag or whistle — each brakeman would apply the brake at their own timing. The result? A chaotic, jerky, and dangerously slow deceleration. The longer the train, the higher the risk.

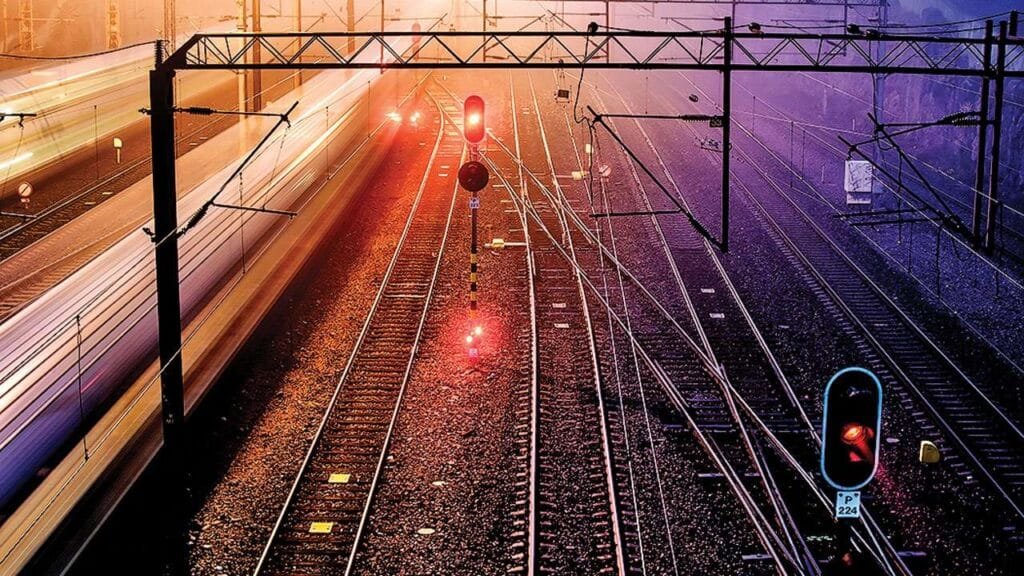

That changed in 1869, when George Westinghouse patented a breakthrough: the air brake. It used compressed air to distribute braking force across the entire train. For the first time, one action in the locomotive could control every wagon. But here’s the catch: the original Westinghouse brake was direct, meaning the system applied air pressure to activate the brakes. Push air in, and the train slows down.

Simple enough — but not safe enough.

Because if a hose burst, or the compressor failed, or the system lost power… no air meant no brakes. In fact, the longer and more complex the trains became, the more dangerous this direct logic turned out to be. That’s when the concept of indirect braking was born — and with it, the most important safety principle in rail braking: fail-safe design.

In the indirect system, which quickly became the standard, the train remains in motion because there is pressure in the brake pipe. To stop, you release air from the pipe, which causes local reservoirs under each car to push air into the brake cylinders. The logic is inverted — and brilliantly so. Because now, if anything fails — a leak, a rupture, a total loss of air — the train stops by default. That’s why modern braking is not just pneumatic, but continuous and automatic: continuous because every vehicle is part of one system, automatic because any failure leads to immediate brake application.

This indirect air brake is now the foundation of rail safety — so foundational, in fact, that it’s required by law in most rail systems across the world. And yet, it’s just one piece of a more diverse braking ecosystem.

But the brake we’ve been talking about so far is actually just one of several used to slow down or stop a train. And to be honest, it’s one of the least used ones!

In normal operating conditions, especially on passenger trains, this type of brake – called the indirect brake – is hardly ever used. The only real exception is on freight locomotives, where it’s still more common.

In fact, many modern train manufacturers even go as far as removing the control knob for the continuous brake from the driver’s cab altogether, just to prevent it from being used incorrectly or accidentally.

So that brings us to the big question: what types of brakes are actually used the most on trains today? And how many different types are there?

Modern trains use a combination of four main braking systems, each with a specific role. Here’s a simple explanation of each:

-

Indirect brake

This is the brake we’ve talked about earlier in the article, and even if it’s not the most used during normal operation, it’s still the most important one for safety. Why? Because it ensures the train can always stop safely — even if something goes wrong. For example, if the train breaks apart and a carriage gets disconnected, this brake will automatically activate on all the separated parts, stopping them independently.

It works by reducing air pressure in a pipe that runs along the entire train, which then activates the brakes on each carriage. It’s not very fast or precise, but it’s essential for emergencies and safety-critical situations. -

Direct brake (also called electric brake)

This is the brake most commonly used while the train is running. When the driver activates it, air is sent directly to the brake cylinders, allowing for quick and smooth braking. It’s often managed by electronic systems, which help control the braking force in a smart and efficient way. It’s reliable, responsive, and ideal for everyday use. -

Magnetic brake

This system uses electromagnets located under the train. When activated, special plates lower toward the rails and create braking force through electromagnetic interaction with the track. In some cases, the plates also touch the rail and add friction. It’s a powerful additional brake, especially helpful in low-grip conditions, like rain or slippery tracks. -

Parking brake

This brake keeps the train from moving when it’s parked, especially on slopes. It works using springs or mechanical systems and doesn’t rely on air pressure — so even if all the air is gone, the brake stays locked. It’s a safety measure that ensures the train won’t roll away when stopped.

But classification is just the beginning. The real complexity lies in coordination. A modern train can’t just “brake hard.” It needs to brake evenly, predictably, and without shaking apart. That’s why systems like the electropneumatic brake (EP) were introduced. These send electronic signals along with pneumatic commands, allowing for near-instantaneous and synchronized brake application across the train — crucial for passenger comfort and avoiding dangerous compression or tension in long consists.

And there’s more. Many trains now include dynamic braking, especially electric and diesel-electric units. Here, the traction motors become generators: they resist rotation, converting kinetic energy into electrical energy. That energy is either dumped into resistors (rheostatic braking) or fed back into the power grid (regenerative braking). It’s highly efficient, especially at high speeds, and drastically reduces wear on friction brakes. But it disappears at low speed — so it can’t replace mechanical systems.

All this braking power, however, is only as good as the system that uses it — and that system must be able to adapt. Trains differ in weight, length, gradient, and speed. So engineers use a metric called the braking percentage: the ratio between braking force available and the total weight of the train. High-speed passenger trains can reach over 100%, while long freight trains often operate around 60%. This number determines how early you must begin braking, how fast you’re allowed to go, and what gradients are safe to descend.

It also determines what happens when something fails. Modern trains have brake isolating devices: valves or switches that allow a malfunctioning brake to be temporarily excluded. But it’s never done casually. Every isolation is recorded, compensated for, and carefully assessed. Too many disabled brakes, and the train must be stopped, shortened, or supported by additional traction units.

In the end, braking is not just a function — it’s the condition for movement. Without the guarantee of controlled deceleration, trains would be reduced to uncontrolled mass. The modern railway network, with its speeds, its schedules, and its trust in technology, is built on one invisible promise: that every train, no matter its size, weight, or location, can stop — completely, safely, and in time.

And that’s why the story of railway braking — from rooftops and hand levers to pressure waves and magnetic fields — is not a footnote. It’s the spine of the whole system.

In the coming articles, we will explore each braking system in detail — how they work, where they’re used, and what makes them critical to the safety and performance of modern trains.

References:

-

UIC (International Union of Railways), UIC Code 540 – Brakes – General Provisions, 5th edition.

-

ERA (European Union Agency for Railways), Technical Specifications for Interoperability (TSI) – Rolling Stock – LOC&PAS.

-

Westinghouse Air Brake Company, Historical Archives and Technical Bulletins.

-

Deutsche Bahn AG, Zugbeeinflussung und Bremstechnik, interne Schulungsunterlagen, 2022.

-

SNCF Réseau, Fiches Techniques de Freinage – Trains de voyageurs et marchandises, 2021.

-

Bombardier Transportation, Braking Systems Overview, Technical White Paper Series, 2019.

- Image Source: Strasburg Rail Road Mechanical Services, “Why the Railway Air Brake & Its Evolution Matters”, blog post, Strasburg Rail Road website, 2022.